1. Team profile

The innovation team for road construction and maintenance materials in special regions was approved in 2015 as a key innovation team in the Ministry of Transport’s priority research areas. The team is led by national and provincial high-level talents, including winners of the Ministry of Education’s “New Century Excellent Talents” program and Shaanxi Provincial Leading Talents in Scientific and Technological Innovation. It consists of nine faculty members: two professors/doctoral supervisors, five associate professors, and two lecturers. Team members hold doctoral degrees from leading universities in China and abroad (such as Chongqing University, Wuhan University of Technology, Chang’an University, Air Force Engineering University, Purdue University, and University College Dublin), covering diverse disciplines including building materials, pavement materials, polymer materials, material chemistry, and mechanics.

The team is headed by Professor Huaxin Chen, doctoral supervisor and State Council special allowance expert, who has been engaged in cutting-edge research on road building materials for many years. He has led and completed numerous national and provincial projects, including the National Natural Science Foundation of China (General Program), the “13th Five-Year Plan” Key R&D Program, the National “12th Five-Year Plan” Science and Technology Support Program, logistics open projects for the Central Military Commission, and the National Western Transportation Construction Science and Technology Project. The team has published over 300 academic papers in high-level international journals, with more than 100 indexed by SCI/EI, obtained over 30 invention patents, and participated in drafting several national and local standards such as Accelerating admixtures for sprayed concrete (GB/T 35159). They have received one Second Prize of the National Teaching Achievement Award and eleven provincial or ministerial-level Science and Technology Progress Awards.

Rooted in western China but serving the whole country, the team focuses on bottlenecks and key scientific challenges in the development of transportation and building materials. Their research is closely aligned with directions such as high-performance transportation building materials, eco-friendly materials, emergency repair and rapid restoration materials, solid waste recycling and utilization, and functional construction materials.

2. Main research directions

(1) Infrastructure de-icing and anti-icing technology

The team focuses on the winter icing safety issues of roads, bridges, and airports in cold northern regions and has carried out systematic studies on the interaction between pavement materials and ice layers over the long term. We have developed a domestically leading ice adhesion testing device that can accurately simulate icing conditions under different temperatures, ice thicknesses, and loading scenarios, and established standardized testing methods and evaluation systems. Through extensive experiments and mechanism analysis, we revealed the effects of material surface energy, micro-texture, and ion distribution on ice adhesion strength and proposed new approaches to reduce ice adhesion. Based on these research results, the team developed efficient anti-icing and de-icing materials and surface treatment technologies, which can significantly reduce road and bridge icing risk and improve winter traffic safety. These technologies have provided scientific design guidance for expressways, bridges, and airports in cold regions and have been applied in multiple trunk highways and key engineering pilot projects with excellent demonstrationresults.

Figure 1. Key technologies for pavement material ice adhesion characteristics and anti-icing

(2) Long-term functional coating and protection system

To address the problem of concrete durability degradation caused by multi-factor coupled corrosion environments such as saline soils, coastal regions, and tunnels, the team has developed a multifunctional coating system that integrates anti-corrosion, flame retardancy, dust suppression, and environmental purification. By adopting advanced techniques such as phase inversion emulsification, emulsion polymerization, and sol-gel processing, the film-forming materials and coating structure were optimized, significantly improving adhesion to concrete substrates. The peel strength of the double-layer coating system reached 2.9 MPa, and the primer adhesion reached 3.4 MPa. After long-term alkaline solution immersion and 28 days of −5 °C freeze–thaw cycling, demonstrating outstanding durability and environmental adaptability. This coating system has been widely applied to municipal guardrails, coastal wave walls, and bridge and tunnel structures in saline soil areas, creating a comprehensive protection system integrating corrosion resistance, flame retardancy, environmental friendliness, and aesthetics. It has significantly extended the service life of transportation infrastructure and reduced maintenance costs throughout the full life cycle.

Figure 2. Preparation and characterization of long-term durable functional coatings

(3) Low-temperature rapid repair and high-toughness materials

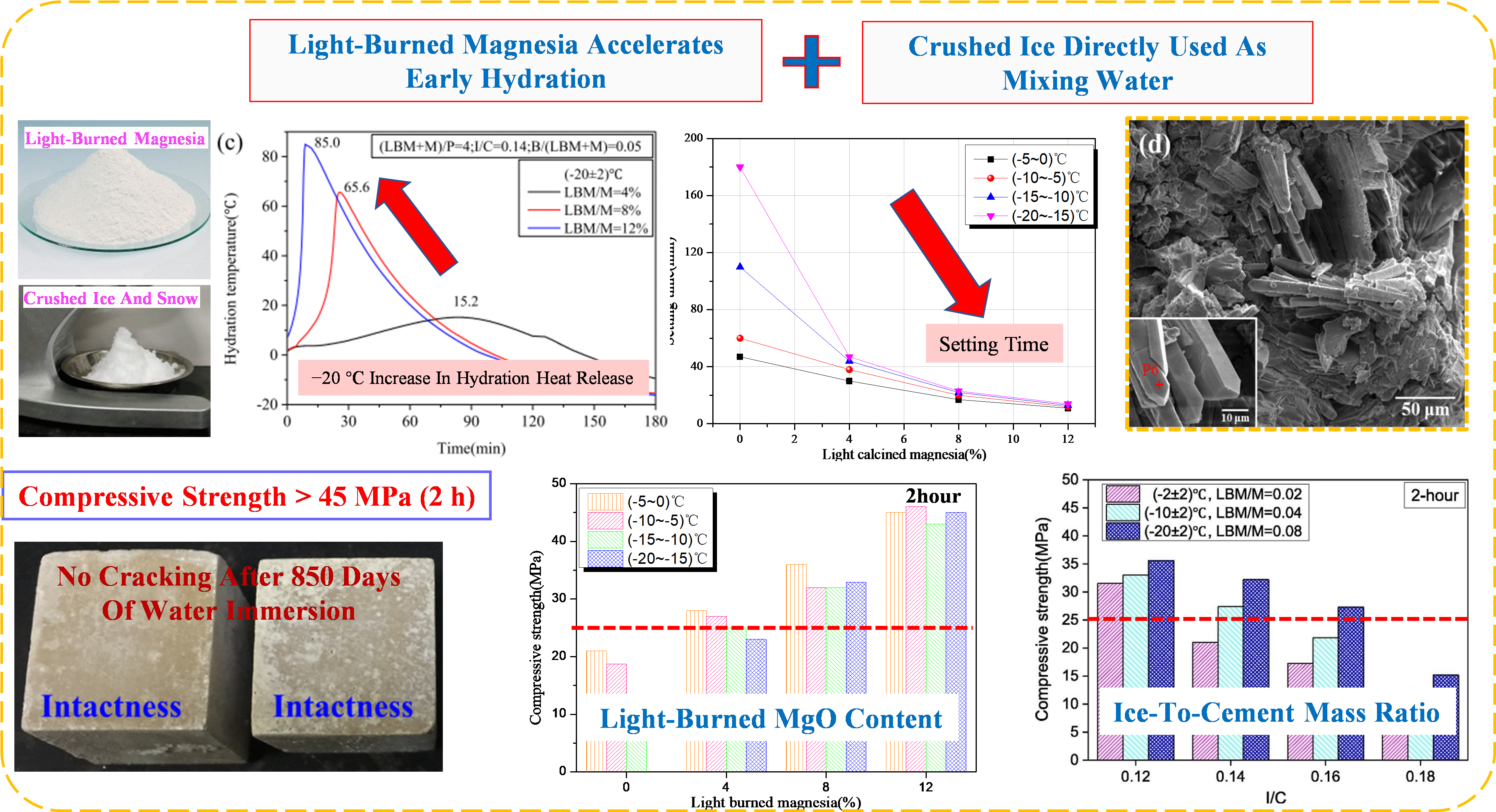

To address the severe winter damage and maintenance difficulties of transportation infrastructure such as roads and bridges in cold regions, the team has developed new low-temperature rapid repair materials and high-toughness concrete systems. By introducing light-burned magnesia and crystal-induced hydration technology, the hydration reaction under low temperatures was significantly accelerated, enabling the repair material to achieve a compressive strength of 40–45 MPa within 2 hours at −20 °C—much higher than conventional materials—thus ensuring rapid reopening to traffic after emergency repairs. Meanwhile, by optimizing aggregate gradation and incorporating fiber reinforcement, the materials demonstrated excellent long-term durability, remaining intact and crack-free after 850 days of water immersion, meeting the long service-life requirements of structures in cold regions. These materials have been applied in highway pothole repairs, tunnel lining rehabilitation, and emergency rescue projects, greatly improving the operational reliability and emergency response efficiency of transportation facilities.

Figure 3. Early hydration and strength development of solid waste-based materials at low temperatures

contects: wangruiyang@chd.edu.cn